Middleeast valve is a topmost Swing check valve supplier in Bahrain. We supply to cities like Sitra, Hidd, Mina Salman and Askar.

A swing check valve is a type of check valve used to prevent backflow in pipelines. It works by allowing fluid to flow in one direction and automatically closing to prevent backflow in the opposite direction.

Structure and Design:

A swing check valve typically consists of a hinged disc, known as the swing disc, mounted within the valve body. The hinge is positioned at the top of the disc, allowing it to freely swing or pivot. When fluid flows in the forward direction, the pressure pushes the disc open, allowing unimpeded flow. However, if the flow reverses, the disc swings back to its closed position, preventing backflow.

The valve body is often cylindrical and features an inlet and an outlet. Some designs may include a lever or counterweight to assist in the closure of the valve and reduce the chances of water hammer.

Working Principle:

The operation of a swing check valve relies on the force of gravity and the flow of fluid. When there is forward flow, the fluid exerts pressure on the disc, causing it to swing open. The swinging motion is unimpeded, allowing the fluid to pass through freely.

During reverse flow or when there is a cessation of forward flow, gravity aids in the closure of the disc. The weight of the disc, coupled with any additional counterweight or lever mechanism, ensures a swift and effective closure, preventing backflow and maintaining the integrity of the system.

Maintenance Considerations:

While swing check valves are generally robust, proper maintenance is essential for optimal performance. Regular inspections should be conducted to check for signs of wear, corrosion, or damage to the valve components. Lubrication of moving parts and the removal of any debris that may impede the swinging motion are crucial for sustained functionality.

Swing Check Valve are cost-effective and low-maintenance, making them an ideal choice for suppliers in Bahrain.

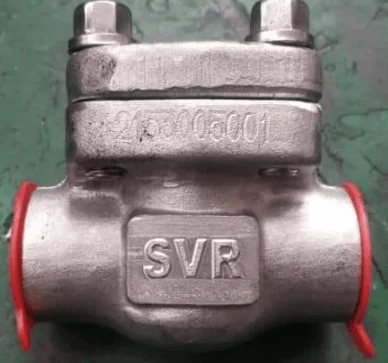

Description:

Available Materials: WCB, WC6, LCC, LCB, WCC, SS304, SS316, CF8M, F51, F53, F55, Aluminium bronze, Cast Iron and Ductile Iron.

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Size: 1/2” to 24”

Ends: Flanged, Buttweld, Socketweld, Threaded

Parts:

- Body

- Disc

- Hinge

- Spring or weight

- Seals

- Handle

- Inlet and Outlet

- Gland packing

- Stem

Advantages:

- It has a relatively low pressure drop across the valve, which means that they do not significantly impede the flow of fluid.

- The design of a swing check valve is relatively simple, which makes it easy to manufacture, install, and maintain.

- It can handle flow in either direction, which makes them suitable for use in systems where the flow direction may change.

- Swing check valves are relatively inexpensive, and are a cost-effective choice for many applications.

- They are easy to operate, and can be opened or closed manually by turning the handle or lever.

Industries which use them

- Oil and Gas

- Water Treatment

- Chemical Industry

- Power Generation Industry

- Marine Industry

- Mining Industry

Visit us: https://www.middleeastvalve.com/product-category/swing-check-valve/