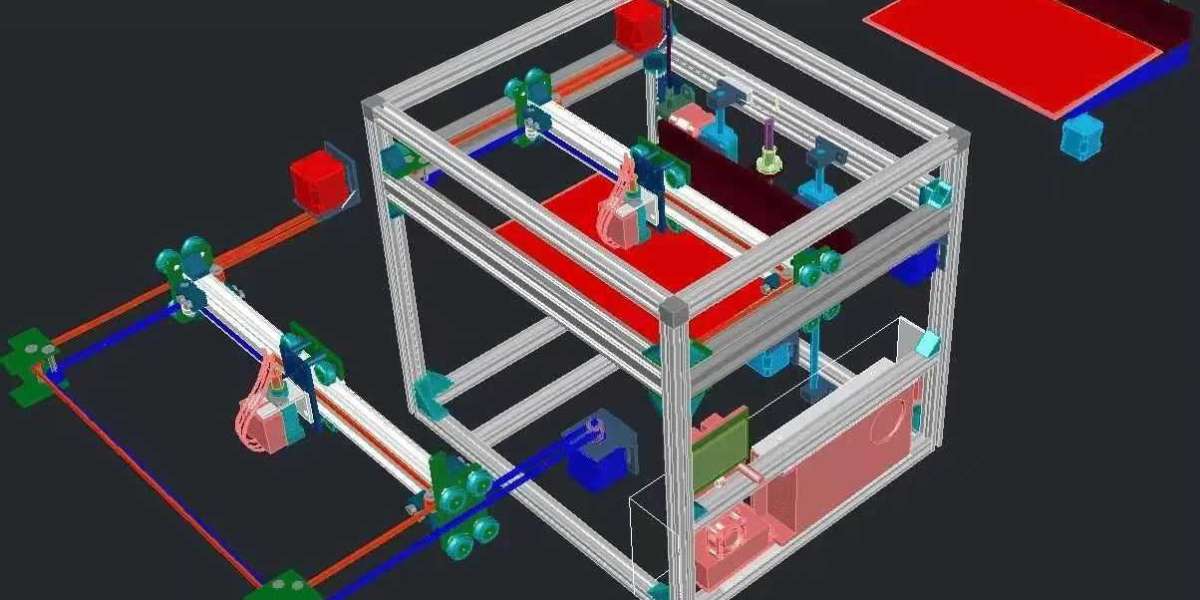

The working principle of the Core XY printer is based on an innovative motion control mechanism.

In this structure, two motors control the movement of the X and Y axes, but unlike the traditional Cartesian motion structure, the Core XY printer achieves movement through a synchronous belt drive system. When the left and right motors rotate in the same direction, the end effector moves in the X-axis direction; When the two motors rotate in reverse, they move in the Y-axis direction. This design not only improves the motion stability, but also greatly improves the printing accuracy and efficiency. Specifically, when one motor rotates and the other stops, the moving platform moves in the direction of ±Y=±X; When the two motors rotate in the same direction, the moving platform moves in the direction of ±X; When the two motors rotate in reverse, the moving platform moves in the direction of ±Y. This motion logic allows the Core XY printer to respond quickly and execute accurately when handling complex print tasks.

To achieve this efficient flat motion, the Core XY printer uses a unique sync band arrangement.

The belts are arranged on two planes, one on top of the other, thus avoiding physical interference between the belts. This design not only optimizes space utilization, but also improves the overall stability of the system. In addition, the stepper motor is installed on the slide frame moving in the X and Y directions, which further ensures the accuracy and stability of the slide frame moving.

It is worth mentioning that the design of the Core XY printer also has advantages in terms of cost control.

Through clever mechanical design, it achieves efficient motion control using relatively few components, thereby reducing overall costs. This makes the Core XY printer more competitive on price, while also giving DIY enthusiasts more room to build and transform on their own.

In terms of transformation and innovation, the Core XY printer also shows great potential.

For example, some enthusiasts have solved the problem of interference in the cross part of the synchronization belt by reversing the direction of the synchronization belt. This design not only maintains the symmetry and beauty of the structure, but also further simplifies the construction process, making the design and construction more convenient. In addition, the component cost can be reduced to a certain extent by replacing a part of the tooth idler with a smooth idler. Case in point: When printing a complex model, such as a statue with multiple overhanging structures and fine features, the motion logic of the Core XY printer is particularly important. When printing the head of the statue, the printer needs to move quickly in the X - and Y-axis directions to precisely deposit the material. The two motors of the Core XY printer work together to ensure that the movement of the print head on both axes is both fast and accurate, enabling the printing of fine features. When dealing with the overhanging part of the statue, the printer needed extremely high motion stability to prevent the material from collapsing under gravity. The Core XY printer provides stable motion support through its unique synchro-belt drive system, ensuring successful printing of the overhang structure.

The Core XY printer is unique in the field of 3D printing with its unique motion logic and design philosophy. Through the collaborative control of two motors, it achieves efficient and stable plane motion, which not only improves printing accuracy and efficiency, but also has significant advantages in cost control. With the continuous progress and innovation of technology, Core XY printers are expected to be widely used in more fields in the future, bringing new development opportunities for 3D printing technology.