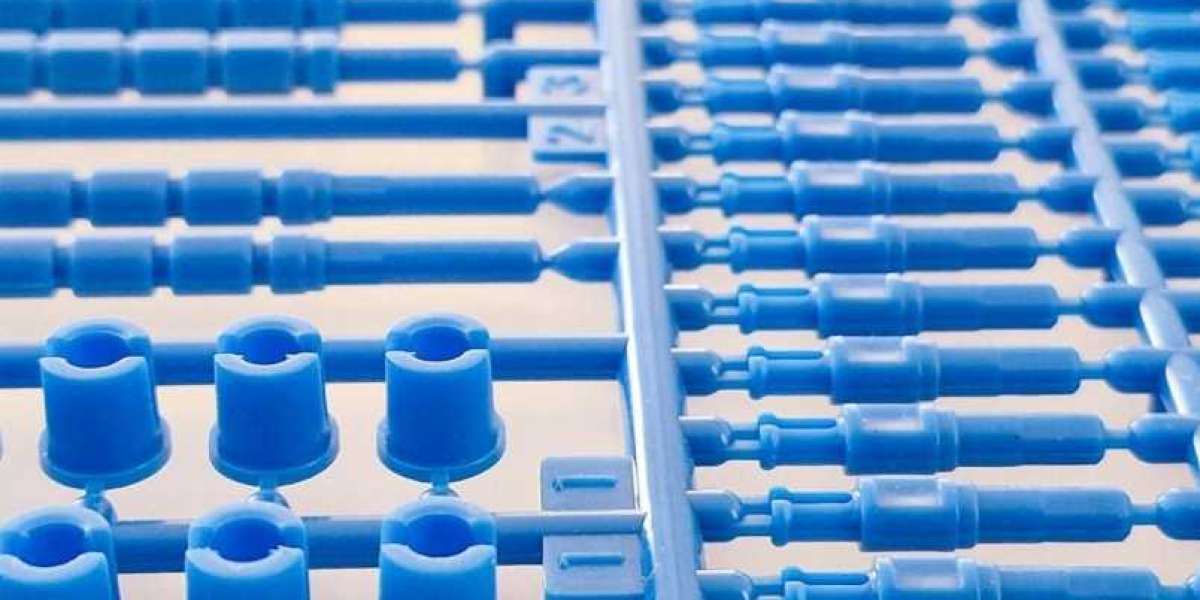

When it comes to plastic injection mold warpage, defects can be caused by several factors including:Inadequate Injection Pressure or TimeInadequate Residence TimeBarrel Temperature Too LowMold Temperature Too LowUneven Mold TemperaturesNozzle Temperature Too LowImproper Flow RateInconsistent Process CycleInadequate Gate SizeIncorrect Gate LocationLack of Ejection UniformityPart GeometryMold Burns Plastic Molded Concepts is a U.S based company that uniquely specializes in molding with engineered resins. We have been thriving in the plastic molding business for 45 years. We have the experience and certified in-house Master Molders, allowing us to take on projects of any complexity. When discussing thermoplastic injection molding, glass-filled plastic is commonly used to enhance part strength and rigidity.Some of the most common glass-filled thermoplastic resins include:ABSLCPPEEKPEIPETPPS If your current molder is struggling with your plastic injection mold design, our specialists at PMC can help. Get in touch with us today!Have questions about our process?

What Is A Shot In Injection Molding Definition

Start a conversation with an expert at PMC today for assistance with your medical injection molding project. Contact Us The demand for innovative, new plastic products that are lighter, faster, stronger and less expensive than metal ones has gained incredible traction in the last decade. Many Original equipment manufacturers (OEMs) have been moving toward the innovative possibilities that engineered resins offer. Proper material selection is a critical injection molded part design consideration to ensure the finished product survives its intended use, environment and compliance requirements. The addition of glass powder or fibers to nylon resin creates this engineering grade resin. Glass is added to polyamides to increase their mechanical strength, rigidity, and hardness. It also makes them more resistant to creep, wear, chemical exposure, and high temperatures. But, with modern advances in engineered resins and plastic molding capabilities, manufacturers are no longer bound by the heavy, expensive and restrictive metal parts of yesterday. Benefits of Engineering Failure Analysis Through Forensic Research in Injection Molding

How To Remove Gate After Injection Molding Machine

When it comes to material selection for medical device plastic injection molding, it’s important to work with a molding company that’s been entrusted by the medical manufacturing industry to identify the best resin for a given device and who specializes in engineered resins. Struggling with warpage in injection molding? Our team at Plastic Molded Concepts can provide expert assistance. Contact us or request a quote today! Warpage in injection molding is a common challenge faced by manufacturers. Warpage refers to the distortion or deformation of a molded plastic part, often caused during its cooling process in the injection molding cycle. This can cause parts to fold, bend, twist, or bow, leading to potential complications in final product assembly. We serve a wide range of industries who need to improve an existing product, transition a part from metal to plastic, or bring an entirely new product to market. Castings are always stronger less prone to stress fracturing. A part machined out of cast material will often give you a resulting stronger part. If machining the part includes sharp corners, this could become a trap into the material selection being completely wrong for the molding process.Size